“Data is key to our everyday operations. It helps us forecast demand, optimize our supply chain, estimate when an order will be ready, and detect the status of an order. If we can’t make sense of our data, we’ve lost.”

Joe DelPercio is no stranger to the importance of data in running a global manufacturing business like Zeus. Joe heads up Data, Analytics, and AI at Zeus, which manufactures advanced polymer components for the world’s most innovative medical device and industrial companies. The company was founded in 1966 and has grown to thousands of employees running plants around the world.

To better serve customers with manufacturing speed and predictability, Joe and his team needed to develop a new system to seamlessly integrate data and business intelligence without disrupting operations. Read on to learn how to learn how he and his team did it.

As demand increased, Zeus accumulated more data across sales, inventory, and operations, resulting in an overwhelming number of Excel spreadsheets and SharePoint lists to manually analyze. This made it difficult for the team to derive meaningful insights and opportunities for revenue growth, potentially leaving millions on the table from missed sales opportunities, customer churn, and operational inefficiencies.

Joe summed it up: “We're losing out on revenue opportunities to sell more parts if we can't identify trends in what our customers are buying.” Purchasing patterns could inform how much of each existing or new product to manufacture. But all of this required many hours of analyst resources, and tools that could integrate notes and comments from production line teams to their Oracle ERP and reporting system (Incorta Data Lakehouse).

The benefits of better connected systems and tools extended to operational efficiency, too. For example, with better data the team could monitor equipment conditions to optimize settings. And they could track down the source of delays to improve the manufacturing process.

Zeus sought a solution that enabled them to move quickly, and one that didn’t require extensive development team capacity.

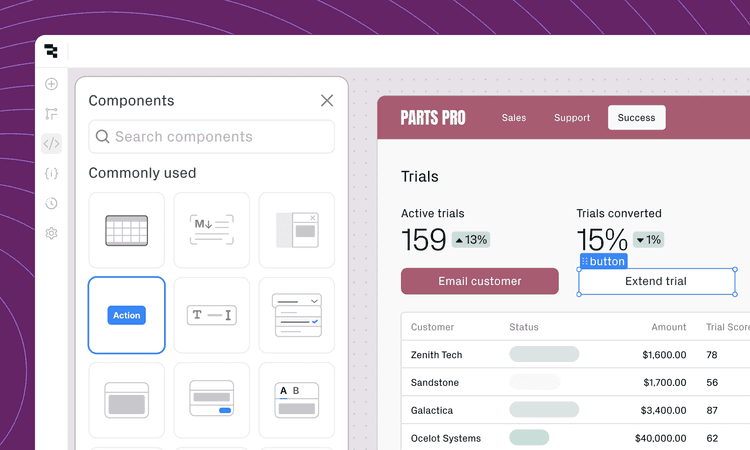

After evaluating several options, Donald Clarke, Manager of Business Intelligence Services and Analytics at Zeus, discovered Retool. “We identified an opportunity to streamline our processes and reallocate resources more strategically. While tools like Power Apps offer some capabilities, our team's strengths were better suited to other high-impact initiatives,” says Donald.

needed a platform to integrate bi-directionally with Zeus's existing systems, including their CRM, databases, and Oracle ERP. Unlike other app development platforms, Retool is data-agnostic and can connect to a wide range of data formats.

Others reasons why Zeus chose Retool:

- Cloud and self-hosted deployments

- Use of standard languages (JavaScript, SQL, Python) so the team didn’t have to learn anything proprietary

- Centralized management of security and governance (SSO, access controls, and data partitioning)

The team first built a data storage system to replace their SharePoint lists. This data storage system would be used to improve the way Zeus operations teams manage inventory, track products, and report on progress. This new system pulls data from their Incorta business intelligence system and SQL database, allowing for data manipulation and analysis without risking the integrity of the raw data. Security was critical, so the team used Retool’s security and governance features to add single sign-on (SSO) and access controls integrated with Okta, and audit logs, along with data partitioning using Retool Spaces.

The impact on Zeus's development speed was immediate. “Our development speed has gone from months to weeks if not hours depending on the apps we're building," Donald reported.

Zeus used Retool to build more apps for their manufacturing process. Justin Law, a corporate planning engineer, used Retool to build a real-time production scheduling system to track order timeliness and production schedules, replacing inefficient spreadsheet-based tracking. This app is critical for Zeus’s sales and analysts teams to ensure that deliveries are fulfilled on time for their customers.

“We've transformed a nearly impossible manual process that would have taken weeks of collaboration into a streamlined solution that our sales team can easily use. What used to take a week now takes an hour for our sales team. For our customers, that's huge; they don't want to wait,” Joe says.

How the app works

The production scheduling system connects machine capacity data from multiple facilities. The system uses priority-based algorithms to calculate delivery dates based on actual equipment availability and order urgency. Through integrating Incorta Pareto analysis and performance metrics, the team monitors key metrics like machine utilization and order cycle times, allowing them to quickly spot and resolve production constraints. The system also pulls in sales forecasts and supplier data to balance upcoming customer demand with available capacity. Since implementation, on-time delivery has improved by 15%, while also reducing production planning time from 2 days to 4 hours—a 92% improvement.

As word spread, other teams at Zeus began using Retool to optimize other parts of manufacturing processes. The company used Retool to develop planning tools for the factory floor, modernize legacy Oracle APEX apps for better performance and efficiency, and built notification systems using Retool Workflows—Retool's automation engine that enables building and scheduling complex business processes, cron jobs, alerts, and ETL tasks through a visual interface and with code. Their team’s adoption of Retool grew quickly, reaching full adoption within months.

To get there, Joe recommends staying focused initially before scaling: “We found Retool offered more features at a better cost. This allowed us to use a ‘Trojan horse’ approach—starting small, getting business and IT buy-in, and then boom! We went from 5 users to 100, then over 1,000. In just a few months, Retool transformed from a small prototype to an enterprise necessity.”

Within a couple of months, Zeus transformed their forecasting and tooling capabilities to drive better decision-making and make manufacturing adjustments faster. By focusing on streamlining these data challenges, the team has unlocked additional profitability through new sales opportunities, customer retention, and operational efficiencies.

The development process with Retool was fast. Justin developed a prototype in two days, and it was in production with users in two weeks. That’s because “developing with Retool meant that 75–80% of the app was already built. I went from nothing to something usable in maybe 16 hours of work.” In comparison, some of their previous custom apps had taken months to develop from scratch.

By building better forecasting apps and tools, Zeus was able to make decisions faster and adjust manufacturing processes for improved outcomes. The tools were easy to use for plant floor users, the sales team, and analysts because they were built directly with their feedback (not requirements docs). With same-day iteration speeds, Zeus could improve app workflows exactly how the end users wanted them. One of Justin's apps saved his team approximately $83,200 per year that was previously spent on data wrangling.

Joe mentions that "user satisfaction is through the roof, and while we haven't fully quantified the financial impact yet, it's significant. We're less reliant on other teams and manual hours, we're sunsetting some of our other tools like SharePoint, and becoming more resilient and aligned with a holistic platform approach.”

Retool enabled Zeus to innovate on their data management and decision-making processes, leading to improved efficiency and customer satisfaction. As Joe puts it, "Retool is now a critical part of our tech stack to drive innovation."

Want to build similar data management systems? Sign up for Retool or schedule a demo.

Reader